Ua ib qho khoom siv tshiab rau kev ua polyvinyl chloride (PVC),Tshuaj nplaum Calcium Zinc (Ca-Zn) PVC Stabilizertau tshwm sim los ua lwm txoj hauv kev zoo dua li cov tshuaj stabilizers uas siv cov hlau hnyav (piv txwv li, txhuas, cadmium). Nws txoj kev sib xyaw ua ke ntawm kev nyab xeeb, kev ua tau zoo, thiab kev ua raws li ib puag ncig daws tau cov kev xav tau tseem ceeb thoob plaws cov khoom lag luam PVC uas xav tau ntau. Hauv qab no yog cov lus qhia ntxaws ntxaws txog nws cov txiaj ntsig tseem ceeb, qhov dav ntawm daim ntawv thov, thiab nws daws cov teeb meem mob ntev hauv kev tsim khoom PVC li cas.

1. Cov Txiaj Ntsig Tseem Ceeb: Kev Nyab Xeeb, Kev Ua Tau Zoo, thiab Kev Ua Raws Cai

Muab Tshuaj Ca-ZnPVC StabilizerNws sawv tawm rau nws qhov kev ua tau zoo ntau yam, ua rau nws haum rau kev ua cov PVC dav dav thiab cov khoom siv siab.

1.1 Tsis Muaj Tshuaj Lom thiab Zoo Rau Ib puag ncig

Tsis muaj cov hlau hnyav uas ua rau muaj kev phom sij (lead, cadmium, mercury, thiab lwm yam), nws ua tau raws li cov cai ib puag ncig thiab kev nyab xeeb thoob ntiaj teb, suav nrog EU's REACH Regulation, RoHS Directive, thiab US CPSIA (Consumer Product Safety Improvement Act). Qhov no tshem tawm cov kev pheej hmoo rau kev noj qab haus huv rau cov neeg ua haujlwm tsim khoom thiab cov neeg siv kawg, thaum zam kev nplua rau cov tuam txhab tsim khoom xa tawm mus rau thoob ntiaj teb.

1.2 Qhov Pom Tseeb thiab Zoo Nkauj Tshaj Plaws

Tsis zoo li qee cov tshuaj stabilizers uas ua rau PVC daj lossis huab, Paste Ca-Zn PVC Stabilizer tswj cov khoom siv kom pom tseeb. Nws khaws cov teeb pom kev zoo txawm tias nyob rau hauv cov khoom PVC nyias lossis xim, qhov tseem ceeb rau cov ntawv thov uas qhov muag pom (piv txwv li, cov khoom ua si pob tshab, cov yeeb nkab kho mob) lossis cov khoom ua haujlwm (piv txwv li, cov yeeb nkab ntshiab rau kev pom dej) yog qhov tseem ceeb.

1.3 Kev Ruaj Ntseg Zoo Tshaj Plaws & Kev Tiv Thaiv Kev Laus

PVC yooj yim puas tsuaj los ntawm cua sov thaum lub sijhawm ua (piv txwv li, extrusion, calendering) thiab oxidative laus thaum siv ntev. Cov stabilizer no tsim ib daim zaj duab xis tiv thaiv ntawm PVC molecular saw, tiv taus kev puas tsuaj los ntawm cua sov (txawm tias ntawm 160–180 ° C kub ua haujlwm) thiab qeeb qeeb UV/oxidation-cuam tshuam brittleness. Kev sim hauv thaj teb qhia tau tias cov khoom tsim nrog nws muaj lub neej ua haujlwm ntev dua 30–50% piv rau cov uas siv cov stabilizers ib txwm muaj.

1.4 Kev Ua Haujlwm Zoo heev & Tsis Muaj Tsw Qab

Nrog kev sib raug zoo nrog PVC resins thiab plasticizers, Paste Ca-Zn PVC Stabilizer ua kom muaj kev sib kis zoo thaum lub sijhawm sib tov - txo cov teeb meem tsim khoom xws li cov khoom sib sau ua ke lossis yaj tsis sib xws. Nws kuj tseem txo qis cov tshuaj lom neeg volatile (VOCs) tso tawm, ua rau cov khoom kawg yuav luag tsis muaj ntxhiab. Qhov no yog qhov hloov pauv rau cov ntawv thov kaw (piv txwv li, cov tshuaj ntxuav tub yees) thiab cov khoom siv rhiab heev (piv txwv li, cov khoom siv kho mob).

2. Kev Siv Tau Ntau Ntxiv

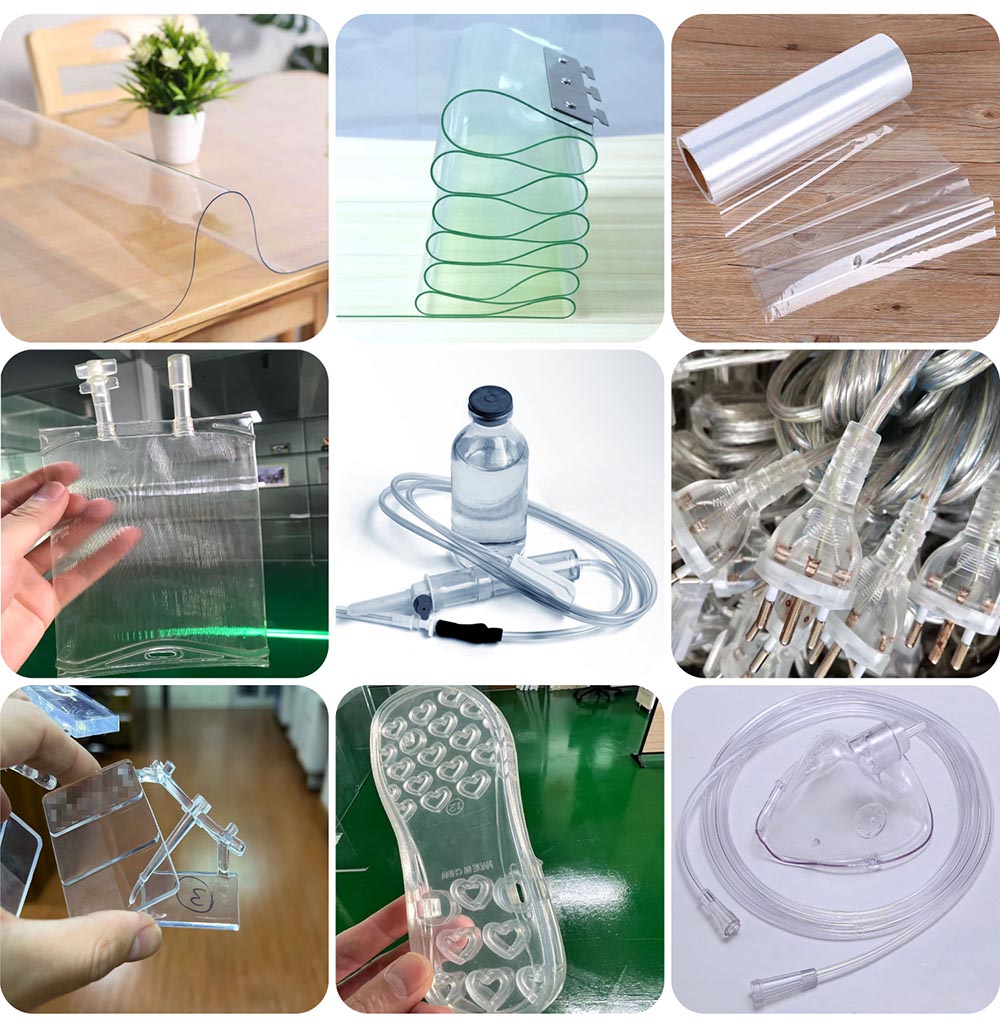

Nws qhov kev hloov pauv ua rau PasteCa-Zn PVC Stabilizerzoo tagnrho rau cov khoom PVC uas pom tseeb, muaj kev nyab xeeb, thiab tsis hnov tsw, uas suav nrog cov neeg siv khoom thiab cov lag luam:

2.1 Cov Khoom Siv PVC Mos thiab Semi-Rigid Uas Muaj Kev Pom Tseeb Siab

• Tsev Neeg & Siv Txhua Hnub:Cov tshuaj ntxuav lub tub yees pob tshab (tiv taus qhov kub thiab txias thiab kov zaub mov), hnab looj tes vinyl pob tshab (qib kho mob lossis qib zaub mov, tsis muaj tshuaj lom), thiab cov khoom ua si PVC yooj ywm (ua raws li EN 71 thiab ASTM F963 cov qauv kev nyab xeeb rau menyuam yaus).

• Kev Lag Luam & Kev Pabcuam:Cov yeeb nkab PVC pob tshab (rau kev xa dej, cua, lossis tshuaj lom neeg, qhov twg pom kev ntawm cov kua dej tiv thaiv kev thaiv) thiab cov ntawv PVC semi-rigid (siv rau hauv cov thawv tso saib lossis ntim khoom rau cov khoom siv hluav taws xob).

2.2 Cov Khoom Siv PVC Kho Mob (Zoo Tshaj, Tsis Muaj Tsw)

PVC kho mob yuav tsum ua raws li kev sib raug zoo thiab kev tsis muaj menyuam. Lub stabilizer no ua tau raws li ISO 10993 (kev ntsuam xyuas kab mob ntawm cov khoom siv kho mob) thiab USP Class VI cov qauv, ua rau nws haum rau:

• Cov khoom siv pab ua pa:Cov ntaub npog qhov ncauj thiab cov raj tshuaj nebulizer (tshuaj tsw qab tsawg ua rau tus neeg mob xis nyob thaum siv ntev).

• Kev tswj cov kua dej:Cov raj xa dej rau hauv cov hlab ntsha (IV), cov hnab ntshav (tiv taus cov tshuaj lom neeg uas muaj cov ntshav lossis cov tshuaj), thiab cov catheter.

• Cov khoom siv txhaj tshuaj:Cov thoob koob txhaj tshuaj thiab cov khoom siv txhaj tshuaj kho mob (tsis muaj tshuaj lom, xyuas kom meej tias tsis muaj cov tshuaj lom nkag mus rau hauv cov kua dej ntawm lub cev).

2.3 Cov Khoom Siv PVC Uas Sib Chwv Tau Rau Khoom Noj

Tsis tas li ntawm kev siv kho mob xwb, nws kuj tau txais kev pom zoo rau cov ntawv thov sib cuag nrog zaub mov (piv txwv li, cov yeeb yaj kiab PVC pob tshab rau kev ntim khoom noj, cov siv conveyor hauv cov chaw ua zaub mov), vim nws ua raws li FDA 21 CFR Ntu 177.1520 (PVC resins rau kev sib cuag nrog zaub mov).

3. Kev daws cov teeb meem tseem ceeb hauv kev tsim khoom PVC

Cov chaw tsim khoom PVC feem ntau ntsib teeb meem ntsig txog kev nyab xeeb, kev ua tau zoo, thiab kev ua raws li txoj cai - cov teeb meem uas Paste Ca-Zn PVC Stabilizer daws tau ncaj qha:

3.1 Tshem Tawm Kev Pheej Hmoo ntawm Cov Hlau Hnyav

Cov tshuaj stabilizer uas muaj cov hlau lead ib txwm muaj kev pheej hmoo ntawm kev raug cov neeg ua haujlwm (los ntawm hmoov av lossis pa phem) thiab kev ua qias tuaj ntawm cov khoom kawg (piv txwv li, cov hlau lead tawm ntawm cov khoom ua si lossis cov khoom ntim khoom noj). Cov tshuaj stabilizer no tsis muaj hlau hnyav tshem tawm cov kev phom sij no, zam kev rov qab hu cov khoom thiab tiv thaiv lub koob npe nrov ntawm hom.

3.2 Kov yeej qhov kev poob ntawm kev pom tseeb hauv kev ua haujlwm

Muaj ntau cov tshuaj stabilizers uas ua rau cov yas PVC lossis cov resins tsis sib haum, ua rau muaj xim tsis zoo lossis tsis pom tseeb. Cov tshuaj nplaum Ca-Zn PVC Stabilizer tsis tshua muaj zog ua rau pom tseeb, txo cov nqi pov tseg rau cov khoom lag luam uas pom tseeb (piv txwv li, tsawg dua 10-15% ntawm cov khoom puas tsuaj hauv kev tsim cov khoom ua si lossis cov raj kho mob).

3.3 Tiv Thaiv Kev Poob Qis Thaum Lub Sijhawm Ua Kub Siab

PVC lwj thaum kub siab, tso cov hydrochloric acid (HCl) tawm thiab ua rau cov khoom tsis zoo nkauj lossis tawg yooj yim. Lub stabilizer no tiv taus cua sov zoo heev ua rau PVC ruaj khov thaum lub sijhawm extrusion lossis molding, ua kom cov khoom zoo sib xws thiab txo lub sijhawm tsis ua haujlwm los ntawm kev xeb ntawm cov khoom siv (ua los ntawm HCl).

3.4 Ua kom tau raws li qhov yuav tsum tau ua ntawm cov ntxhiab tsw thiab cov khoom siv sib xws rau cov chaw muaj kev phom sij

Cov khoom siv kho mob thiab cov khoom siv hauv tsev PVC feem ntau tsis tau daim ntawv pov thawj vim muaj cov ntxhiab tsw phem lossis cov tshuaj lom uas tawm los. Cov tshuaj stabilizer no tso tawm VOC tsawg thiab cov khoom tsis muaj tshuaj lom ua kom ua raws li kev kuaj mob biocompatibility thiab cov qauv tsw phem hauv tsev, ua kom lub sijhawm xa khoom mus rau kev lag luam sai dua.

Cov Tshuaj Calcium Zinc PVC Stabilizer txuas qhov sib txawv ntawm kev nyab xeeb, kev ua tau zoo, thiab kev ua raws li txoj cai rauCov chaw tsim khoom PVCNws cov qauv tsis muaj tshuaj lom, tus phooj ywg ib puag ncig ua tau raws li cov cai thoob ntiaj teb, thaum nws cov pob tshab, kev ruaj khov, thiab kev ua tiav ua rau cov khoom zoo dua thoob plaws cov neeg siv khoom, kev lag luam, thiab kev kho mob. Los ntawm kev daws cov teeb meem tseem ceeb xws li kev ua qias tuaj ntawm cov hlau hnyav, kev poob pob tshab, thiab kev puas tsuaj thermal, nws tau dhau los ua cov khoom siv tseem ceeb rau cov ntawv thov PVC muaj nqis - tshwj xeeb tshaj yog cov uas xav tau kev nyab xeeb lossis cov qauv zoo nkauj.

Lub sijhawm tshaj tawm: Lub Yim Hli-29-2025