Cov yeeb nkab PVC (Polyvinyl Chloride) muaj nyob rau hauv cov khoom siv niaj hnub no, suav nrog cov kav dej, cov dej ntws, cov dej xa tuaj, thiab kev thauj mus los ntawm cov kua dej hauv kev lag luam. Lawv qhov nrov yog vim muaj qhov zoo: kev tiv taus tshuaj lom neeg, kev siv nyiaj tsim nyog, thiab kev ruaj khov ntawm cov qauv. Txawm li cas los xij, PVC cov qauv molecular - uas muaj cov vinyl chloride rov ua dua - ua rau nws yooj yim rau kev puas tsuaj hauv qab thermal, oxidative, thiab UV kev ntxhov siab. Qhov no yog qhov uasCov khoom siv PVC stabilizerua lub luag haujlwm tseem ceeb: lawv txo qhov kev puas tsuaj, ua kom cov yeeb nkab tseem muaj kev ruaj khov thiab kev ua tau zoo thoob plaws lawv lub neej kev pabcuam. Hauv qab no yog kev tshuaj xyuas ntxaws ntxaws ntawm lawv cov ntawv thov, cov txheej txheem, thiab cov qauv xaiv hauv cov yeeb nkab PVC.

1. Vim li casUa PVCCov Khoom Siv Yeeb Nkab Yuav Tsum Muaj Cov Khoom Ruaj Khoov

PVC raug kev puas tsuaj tsis rov qab thaum raug rau qhov kub siab (feem ntau hauv cov txheej txheem extrusion lossis txhaj tshuaj molding) lossis kev ntxhov siab ib puag ncig ntev (piv txwv li, tshav ntuj, dej noo, lossis tshuaj lom neeg raug). Txoj kev puas tsuaj tseem ceeb yog dehydrochlorination: cua sov lossis UV lub zog tawg cov C-Cl bonds tsis muaj zog, tso hydrochloric acid (HCl) thiab pib ua cov saw hlau uas ua rau polymer saw hlau tawg. Qhov no qhia tau tias:

• Xim tsis zoo (daj los yog xim av)

• Poob lub zog thiab kev ywj pheej ntawm kev cuam tshuam

• Tawg los yog tawg yooj yim, ua rau tsis muaj zog xau

• Kev ua qias tuaj ntawm cov kua dej uas raug thauj mus los (qhov tseem ceeb hauv cov dej haus)

Cov khoom ruaj khov cuam tshuam cov txheej txheem no, ua rau lawv tsis tseem ceeb hauv kev tsim cov yeeb nkab PVC.

2. Cov txheej txheem ntawm PVC Stabilizers hauv Cov Yeeb Nkab Fittings

Cov khoom ruaj khov ua haujlwm los ntawm ntau txoj hauv kev sib koom ua ke los tiv thaiv PVC:

•Kev tshem tawm HCl:Tshem tawm cov hydrochloric acid uas tso tawm, tiv thaiv nws los ntawm kev ua kom puas tsuaj ntxiv.

•Kev Tiv Thaiv Dawb Radical:Tshem tawm cov kev hloov pauv saw hlau uas pib los ntawm cua sov lossis UV-generated free radicals.

•Kev Sequestration Hlau Ion:Khi cov hlau tsis huv (piv txwv li, hlau, tooj liab) uas ua rau kev puas tsuaj sai dua.

•UVKev Tiv Thaiv:Kev cuam tshuam lossis nqus cov hluav taws xob UV, qhov tseem ceeb rau kev siv cov yeeb nkab sab nraum zoov (piv txwv li, kev ntws dej saum av).

•Kev Pab Cuam Lubrication:Qee cov stabilizers (piv txwv li, UV stabilizers), calcium stearate txo qhov kev sib txhuam thaum lub sijhawm ua, tiv thaiv kev kub dhau.

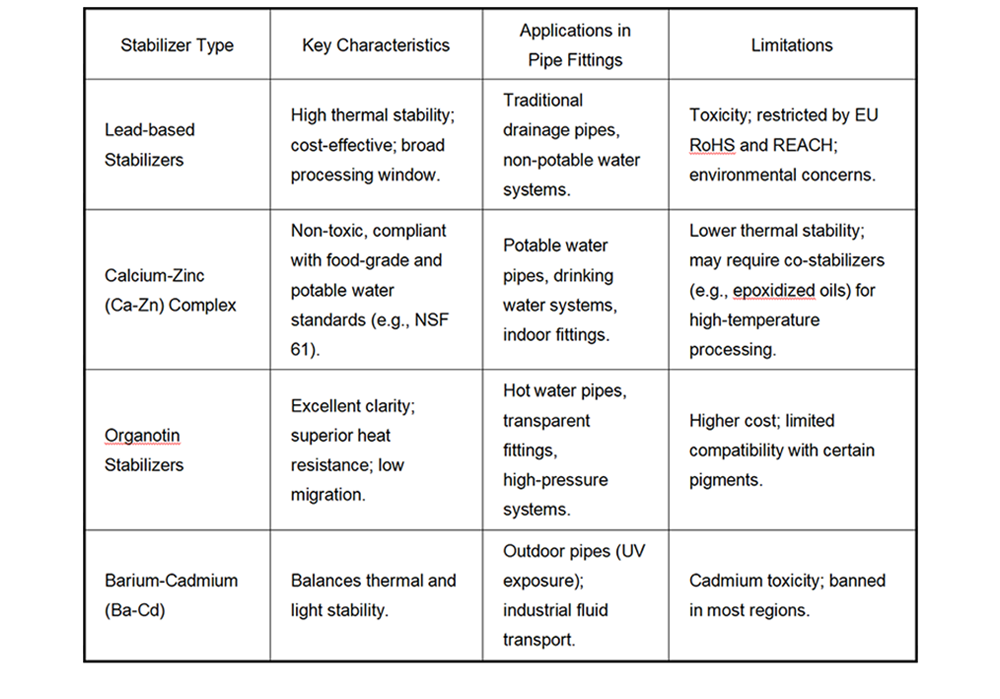

3. Hom Stabilizers Siv Hauv PVC Pipe Fittings

Qhov kev xaiv ntawm cov stabilizer nyob ntawm cov xwm txheej ua haujlwm, cov kev cai siv kawg, thiab kev ua raws li txoj cai. Cov hom feem ntau suav nrog:

4. Cov Qauv Xaiv Tseem Ceeb rau Cov Khoom Siv Yeeb Nkab

Thaum teev cov stabilizers rau cov yeeb nkab PVC, cov chaw tsim khoom yuav tsum xav txog:

•Cov Txheej Txheem Ua Haujlwm:Qhov kub ntawm kev rho tawm/kev pwm (160–200°C rau cov kav dej) thiab lub sijhawm nyob ntev qhia txog qhov xav tau kev ruaj khov ntawm thermal. Cov txheej txheem kub siab (piv txwv li, cov kav dej kub) xav tau cov stabilizers uas tiv taus cua sov zoo (piv txwv li, organotin).

•Ib puag ncig siv kawg:Cov kav dej rau dej haus xav tau daim ntawv pov thawj NSF/ANSI 61 lossis WRAS, nyiamCa-Znlossis cov tshuaj organotin stabilizers. Cov kav dej sab nraum zoov xav tau cov tshuaj UV stabilizers piv txwv li, cov tshuaj hindered amine light stabilizers (HALS).

•Kev Ua Raws Cai:Kev txwv thoob ntiaj teb rau cov hlau hnyav (Pb, Cd) thawb kev lag luam mus rau lwm txoj hauv kev uas tsis ua rau ib puag ncig puas tsuaj (Ca-Zn, cov tshuaj stabilizers uas ua los ntawm cov organic).

•Tus nqi piv rau kev ua tau zoo:Txawm hais tias cov khoom ruaj khov uas ua los ntawm cov hlau lead pheej yig dua, cov nqi mus sij hawm ntev (piv txwv li, kev nplua nyiaj rau kev cai lij choj, kev sib tw rov ua dua tshiab) nyiam cov kev xaiv uas ruaj khov.

5. Cov Qauv Tshiab hauv Kev Siv Tshuab Stabilizer

Thaum cov kev cai ib puag ncig nruj dua thiab kev ruaj khov tau txais qhov tseem ceeb, kev lag luam yeeb nkab PVC tab tom hloov mus rau:

•Cov Txheej Txheem Ca-Zn Ua Haujlwm Zoo:Txhim kho nrog cov co-stabilizers (piv txwv li, polyols, zeolites) kom phim cov kev ua haujlwm thermal ntawm cov kev xaiv ua los ntawm cov hlau lead.

•Cov Stabilizers Ntau Yam:Kev sib xyaw ua ke ntawm kev ruaj khov ntawm thermal, kev tiv taus UV, thiab kev lubrication hauv ib qho tshuaj ntxiv kom yooj yim rau cov qauv.

•Cov Khoom Siv Bio-Based Stabilizers:Tau los ntawm cov peev txheej rov ua dua tshiab (piv txwv li, cov esters uas yog los ntawm cov nroj tsuag), ua raws li cov hom phiaj kev lag luam ncig.

Cov khoom siv PVC stabilizeryog lub hauv paus rau kev ua tau zoo thiab lub neej ntev ntawm cov yeeb nkab PVC, ua rau lawv siv tau zoo thiab txhim khu kev qha thoob plaws cov khoom siv tseem ceeb. Txij li kev tiv thaiv kev puas tsuaj thaum lub sijhawm tsim khoom mus rau kev ua kom ntseeg tau tias muaj ntau xyoo ntawm kev pabcuam hauv qhov chaw ib puag ncig hnyav, lawv lub luag haujlwm tsis tuaj yeem hloov pauv tau. Raws li kev lag luam hloov pauv, kev tsom mus rau qhov tsis muaj tshuaj lom, cov stabilizers ua tau zoo - tshwj xeeb tshaj yog calcium-zinc complexes - yuav tsav kev tsim kho tshiab, sib npaug kev ua haujlwm nrog lub luag haujlwm ib puag ncig. Rau cov engineers thiab cov chaw tsim khoom, kev xaiv cov stabilizer zoo tsis yog tsuas yog kev xaiv txuj ci tab sis kev cog lus rau kev ua haujlwm ntev, kev nyab xeeb, thiab kev ua raws li txoj cai.

Lub sijhawm tshaj tawm: Cuaj hlis-02-2025